Research on reduction of friction loss in reciprocating sliding contact

Yilmaz Emir, Assistant Professor

Faculty of Science and technology, Department of Engineering and Applied Sciences

- Research

【Abstract】

Energy efficiency is included in SDG 7.3, where it targets global progress on energy efficiency by doubling the rate of improvement in energy efficiency by 2030.

There are many machine elements with a reciprocating motion. Most of the time, these elements are in contact with each other. These contacts create heat due to friction, which is called heat loss. By lowering the heat dissipation from contact surfaces, reciprocating motion can be achieved more efficiently.

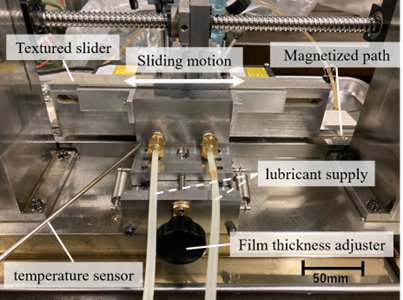

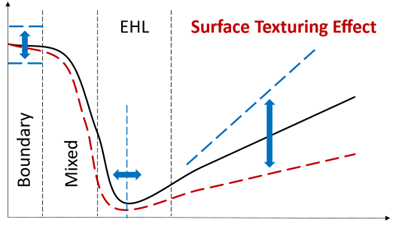

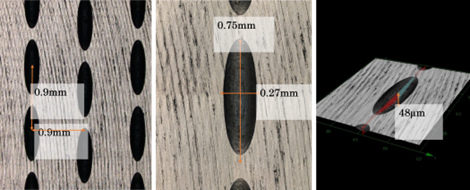

In our laboratory we are working on various surface micro-textures that help to reduce these frictional losses. We have built a novel experimental apparatus to measure frictional forces between two parallel surfaces under hydrodynamic lubrication regime.

【Future Prospects】

By creating a general guideline for surface micro-texture parameters (dimensions, orientation, areal density, etc.), we are aiming to lower the energy consumption by lowering frictional losses in reciprocating surfaces. As the internal combustion engine (ICE) technology continues to prosper via carbon-free/neutral fuels (hydrogen, ammonia, e-fuels etc.), rigorous research in power transmission is still vital for further improvement. Frictional losses account for about 10% of the total mechanical losses in conventional ICEs, whereas the piston-liner interface accounts of 50% of these losses.

A proper guideline for surface micro-textures would increase the overall efficiency, enabling lowered fuel consumption and increased mileage.